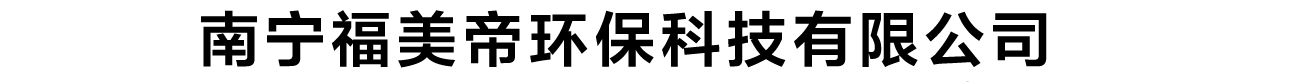

This machine offers health care facilities a better solution to the destruction of expired/discontinued drugs, with strict accountability.

|

Nanning Famed Environment Protection Technology Company Limited |

|

This machine offers health care facilities a better solution to the destruction of expired/discontinued drugs, with strict accountability.

Slow speed Dual shaft dual shredding system Cross Crushing shredder

The machine is used to effectively dispose of pharmaceutical waste such as Aluminum / Plastic blister packing,

Ointments tubes, Syrup bottles, Glass ampoules vials etc. It helps in prevention of reuse of pharmaceutical waste

and also acts as identifier that the waste is safe to dispose off.

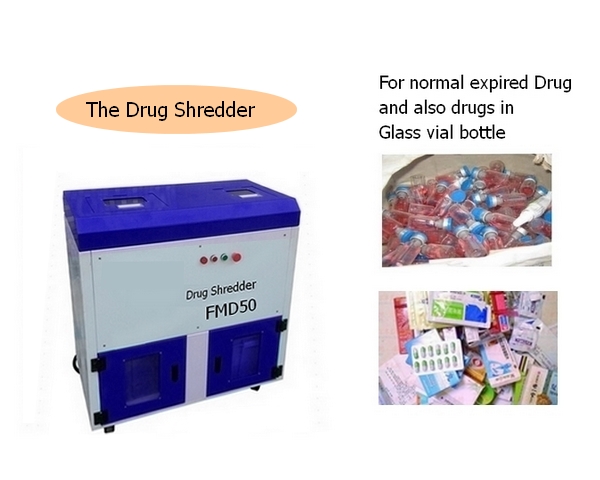

It have 2 different shredding system for shredding different kinds of medical drug waste,the plastic and paper,Aluminum one and the glass bottle one into small pieces.

Product usage

Hospital, clinic, laboratory and so on.

Main Feature:

Double shaft,double shredding chamber. |

Operation panel |

|

|

This machine choose double shredding systems, and the medical waste will become small pieces after grinding and shredding, so that to reduce the volume by 85%.the knives in each set of machine is durable and it is made of special steel and anti-rust and with long life span. |

|

There is various button for different function “START” “STOP” “EMERGENCY STOP” “POWER LIGHT”

|

Waste Collection |

Safety protection |

|

|

With plastic container of waste collection, all waste will fall into the plastic container . |

Electric Leakage protection, Over voltage and over current protection; Interface safety voltage; Emergency stop function; Mild steel body and resistance to breakdown; With earthing conductor; Automatic Reverse step function when shredder becomes stuck, Safe lid and door open function-the electric power will be automatic shut off when the lid or door is open. |

|

MaterialThe body is made of mild steel powder coated , anti-rust, and the waste collection container is made of plastic andthe blade is made of SKD11 |

||

Good structure |

More safety |

|

|

With good appearance as well as good function the height of the waste inlet is suitable for putting in the waste, and the operation panel is convenient for operation, with plastic shredding function and glass waste shredding function. |

We use low speed motor and no risk of the waste fly out of the shredding chamber

|

|

with castors |

High efficient |

|

|

With 4 castors, easy for movement |

you can fill whole bags of waste one time and no need to fill the waste continuously. |

|

Easy to operate |

Super low noise |

|

|

With operation panel and the operator can operate it with just minutes training. |

Its working noise is about 60-70dBa, so it is more suitable for hospital use. |

Parameter:

|

Destroying method |

Electric Double shaft cutting |

|

Product size |

1000*600*1100mm |

|

Crushing capacity |

50kg normal drug waste per hour, 100kg glass bottle waste per hour |

|

Power supply |

380V,50Hz, three phases power supply |

|

Internal protection |

overload protection , leakage protection |

|

|

Thermal hypersensitivity protection, |

|

Interface voltage |

Safety low voltage on the operation panel. |

|

Output power |

2200VA |

|

Material of shell |

Mild steel powder coated |

|

Temperature |

in operation:-5°C~+50°C stored:-20°C~+55°C |

|

Relative humidity |

60%~80% |

|

Waste collector |

2pc of Waste collector |

|

Number of knife |

10pcs for each chamber |

|

Waste inlet size |

315mm*250mm(for plastic), 250mm*230mm(vial bottles) |

|

Motor |

Quiet and low speed motor. |

|

Low noise |

60 - 70 dB (A) |

|

Rpm |

35 |

|

Destroying material |

plastic utensils, syringes, test tubes, ELISA plate, dish, dilution cup, straw, tip, urine cup and so on |

|

Vial bottles |

|

|

Weight |

400kg |